PRODUCT OVERVIEW

Explore all processes involved in pellet production and each equipment required.

PROCESSING FOR RAW MATERIALS

PROCESSING FOR FINISHED PELLETS

Whether you are producing animal feed pellets or biomass pellets, before pelletizing, your feed formulation (grains, soybean meal, oil meal, grasses, etc.) and biomass raw materials (crop straw, wood processing waste, industrial organic waste, municipal solid organic waste, etc.) need to be pre-processed and treated to become a powder suitable for pelletizing. This process usually consists of chipping, crushing, drying, mixing and other procedures.

01

Wood Chipper

his horizontal-fed drum wood chipper machine has the advantages of compact structure ,high efficiency, easy to operate.

02

Hammer Mill

Feed Hammer Mill widely used in the crushing of raw materials for animal feed processing enterprises, and then used to produce high-grade animal feed and aquatic feed.

learn more →03

Rotary Dryer

he body is slightly tilted so that the discharge end is lower than the feed end to transport material through the dryer under the force of gravity.

04

Mixing Machine

Mixing mild, high uniformity, no segregation; smooth transmission, low wear; can be equipped with multiple atomizing nozzles for liquid addition; easy maintenance.

learn more →

PELLETIZING FOR RAW MATERIALS

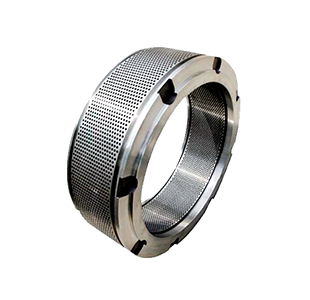

Pelletizing is a process whereby treated raw materials are processed into tight, uniformly sized cylindrical pellets. Of course different applications require different pellet sizes. With the quick release device you can easily change the pelletizer ring die for the production of different pellet sizes. Before changing it is recommended to talk to a technician or contact us directly.

01

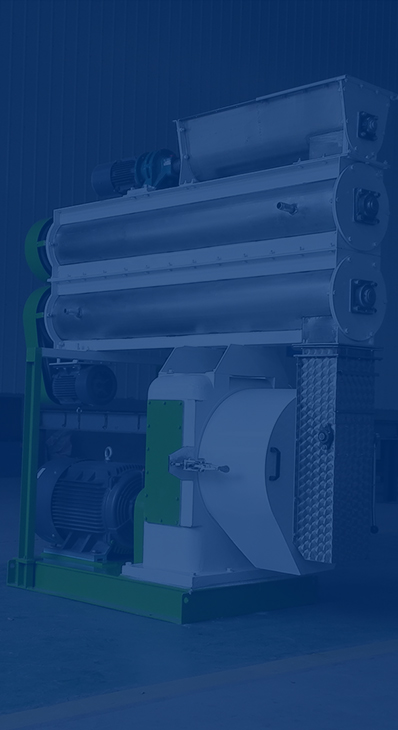

Animal Feed Pellet Machine

The material passing through the modulator enters the granulation chamber and rapidly extruded through the ring die and the press roller to form cylindrical pellets.

learn more →02

Biomass Pellet Machine

Fuel pellet making machine is mainly used to produce fuel pellets or other biomass pellets. The pellets used in power plants or home combustion, have higher combustion values and are to ...

learn more →03

Twin-Screw Aquatic Feed...

The material is fully matured between the screw and the screw sleeve by high temperature and high pressure, and then extruded to form a floatable expanded pellet.

learn more →

After processing at high temperatures and pressures, the temperature of the freshly produced pellets is so high that they require further processing before they can be packaged and stored for use.

01

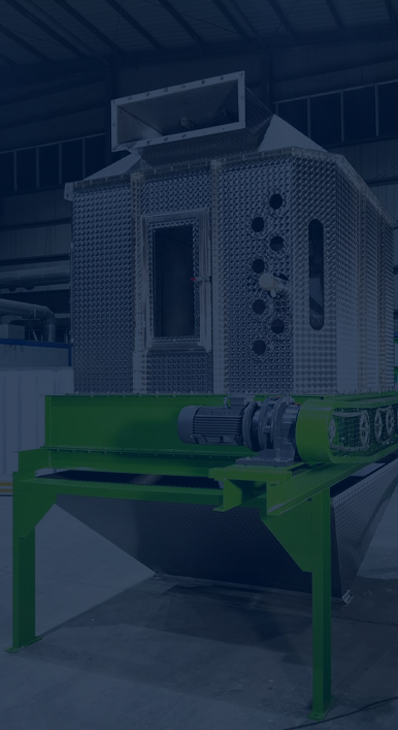

Counter-Flow Pellet Cooler

New feeder to ensure that the spread of material sufficiently homogeneous, thorough cooling and significantly reduced breakage rate, adjustable range of fabrics, a small power ...

learn more →02

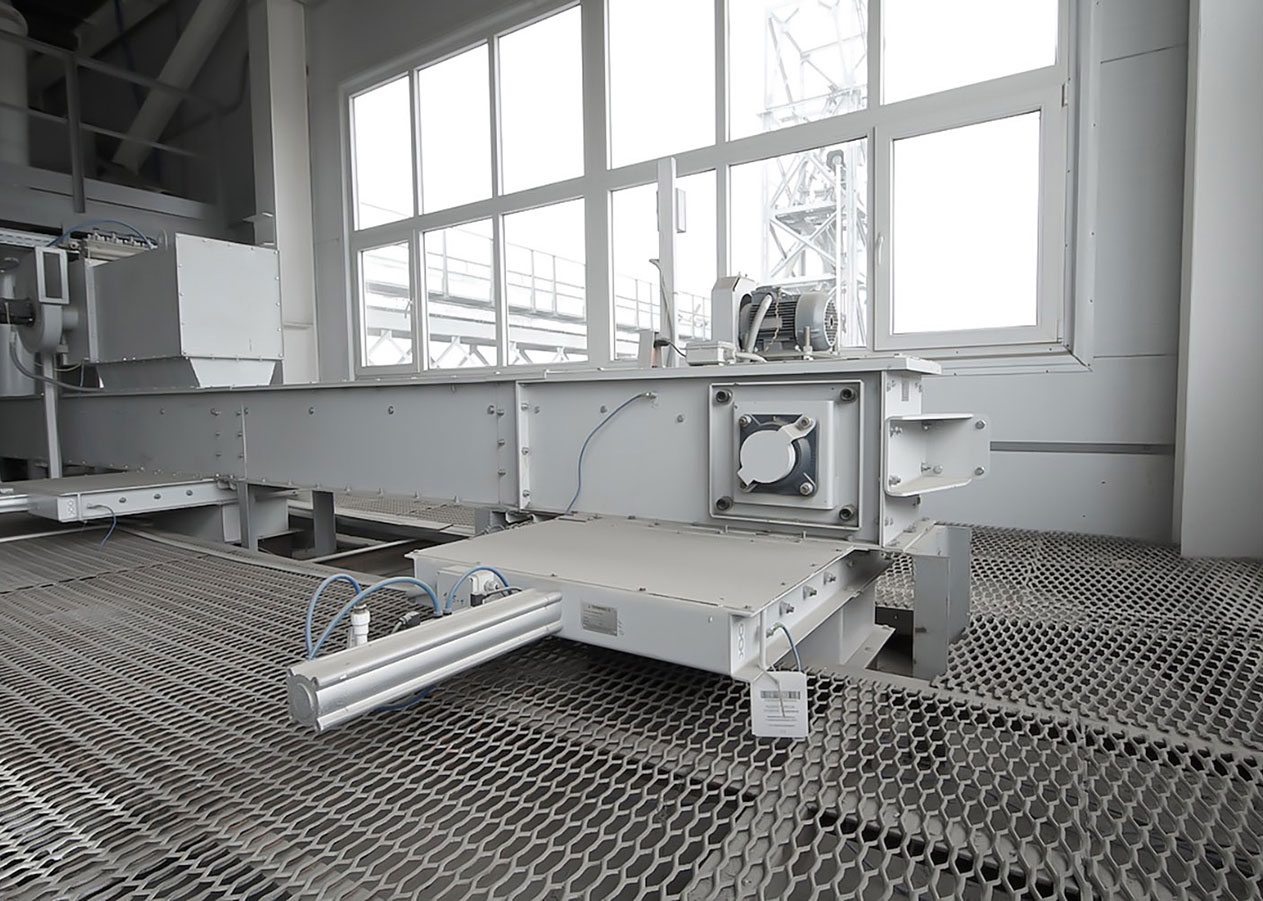

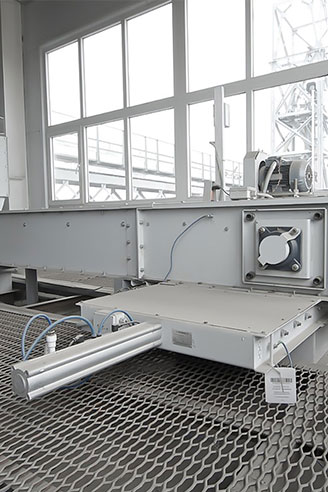

Vibration Screen Classifier

Vibrating screens are used in the production of feed to screen for impurities and grades.

03

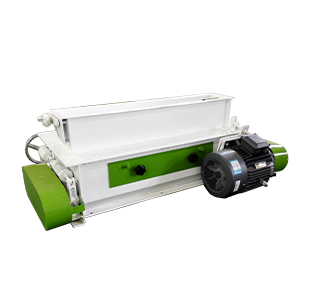

Pellet Crumble

The crumbler adopts the principle of the differential speed of the roller to extrude and shear the incoming material, so that the large granular material is broken into irregular ...

learn more →04

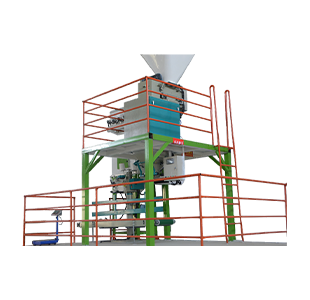

Automatic Bagging Sy...

Consists of a finished storage bin and weighing system for packaging finished feed pellets.

PELLETIZING FOR RAW MATERIALS

Pelletizing is a process whereby treated raw materials are processed into tight, uniformly sized cylindrical pellets. Of course different applications require different pellet sizes. With the quick release device you can easily change the pelletizer ring die for the production of different pellet sizes. Before changing it is recommended to talk to a technician or contact us directly.

01

Rotary Distributor

Supply material from one point to multiple points by means of automatic adjustment and fixed position.

learn more →02

Bucket Elevato

With the reciprocating structure, through continuous feeding and throwing, the effect of lifting the material is achieved.

learn more →03

Cylinder Pulse Dust Re...

Cylinder pulse dust remover refers to removing dust adhering to a filter medium (bag or filter cartridge) by blowing compressed air.

learn more →Pelletizing is a process whereby treated raw materials are processed into tight, uniformly sized cylindrical pellets. Of course different applications require different pellet sizes. With the quick release device you can easily change the pelletizer ring die for the production of different pellet sizes. Before changing it is recommended to talk to a technician or contact us directly.

01

Wood Chipper

his horizontal-fed drum wood chipper machine has the advantages of compact structure ,high efficiency, easy to operate.

02

Hammer Mill

Feed Hammer Mill widely used in the crushing of raw materials for animal feed processing enterprises, and then used to produce high-grade animal feed and aquatic feed.

learn more →03

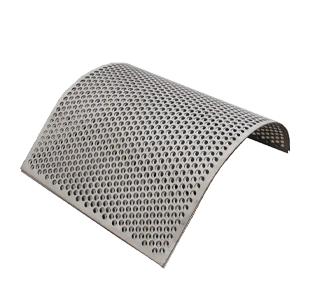

screen mesh

This series crusher is equipped with a forced feeding device, which is mainly suitable for the crushing of lighter materials such as alfalfa, straw, chaff, grass and etc.

learn more →04

Crusher Hammer

he body is slightly tilted so that the discharge end is lower than the feed end to transport material through the dryer under the force of gravity.

learn more →

Quality Assurance

RICHI Machinery guarantees top-grade equipment built to rigorous quality standards.

Product Warranty

Comprehensive warranties provide peace of mind and protect your investment.

Customer Service

Dedicated customer support assists clients through every stage of their project.

Secure Payment

Secure payment options ensure customer confidence and transaction safety.

Global Delivery

Reliable global logistics ensure timely delivery, no matter your location.