Animal Feed Pellet Machine with Unlock Maximum Efficiency

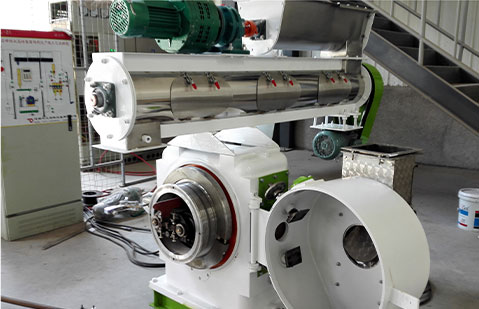

Optimized feed inlets, well-planned conditioners, efficient pelletizing chambers and stable Siemens motors, together with the RICHI Machinery's high-specification body just built, are enough to make it the heart of pellet production.

Apply

Brand

RICHI

Brand

Model

Capacity

PARAMETER TABLE

The output of our small feed pellet machine is 1-2 tons per hour, which is more suitable for small farms or small animal feed mills, so that the feed pellet produced can be used for own use or sold. The following are some of the features of RICHI feed pellet machines and their advantages compared to other companies' products.

| More | Capacity(TPH) | Capacity(TPH) | Capacity(TPH) | Capacity(TPH) | Capacity(TPH) |

|---|---|---|---|---|---|

| SZLH250 | 22 | 22 | 22 | 22 | 22 |

| SZLH250 | 22 | 22 | 22 | 22 | 22 |

RICHI's Technological Innovations in Animal Feed Pellet Machine.

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of animal feed production.

Feeding and tempering systems

The optimized conditioning system with inverter feeding system improves the safety, nutritional value and maturation of the raw material to a great extent. This improves the overall quality of the feed from the source and ensures healthy feeding.

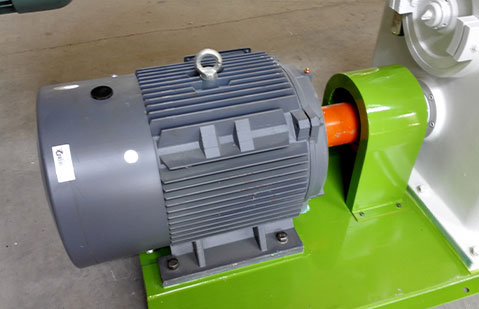

Drive system

High-end Siemens industrial grade drive motor drives the drive shaft of RICHI animal feed pellet mill, which is more stable and durable than traditional belt drive. In the long run, this not only improves efficiency but also saves maintenance costs.

Structure and material

The body of the machine is made of high quality and high specification alloy steel, which is sturdy and durable, reduces resonance and runs stably. The parts that come into contact with the raw material are made of high grade stainless steel, which does not affect the raw material in any way and greatly improves corrosion resistance.

Control and Safety

Each feed pellet mill is equipped with an independent electric control system and safety stop function. It can not only avoid losses caused by perceived errors, but also effectively protect the pellet mill and subsequent production equipment.

Your Seamless Buying Process: From Order to After-Sales Support

Discover our streamlined buying process that makes it simple and efficient for you to get a complete animal feed pellet production plant. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

Complete Solutions For Biomass Pellet Production

Customize Biomass Pellet Solutions Immediately

Raw Material Handling

Essential for preparing and conditioning materials to ensure uniform quality before pelletizing.

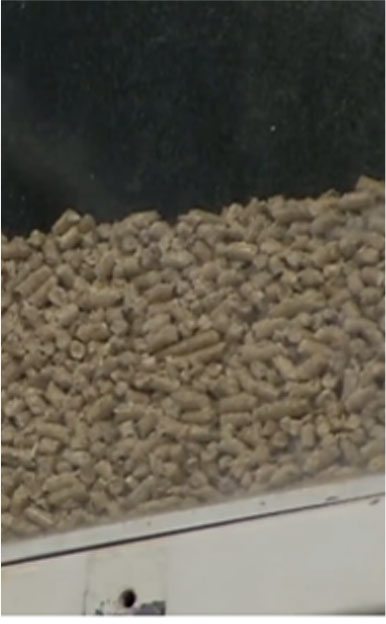

Pelletizing

The core process where prepared materials are compressed into dense, high-quality feed pellets.

Finished Pellet Handling

Involves cooling, screening, and packaging to maintain pellet integrity and ready them for use or sale.

Auxiliary Equipment

Supports the production line by enhancing material flow, reducing downtime, and maintaining operational efficiency.

Accessories

Includes essential components like ring dies and rollers, crucial for consistent pellet production and machine performance.

RICHI MACHINERY__

Global case studies

Founded in 1995, Richi Machinery is mainly engaged in the R&D and manufacturing of equipment required for pellet engineering such as feed mills, biomass wood pellet plant, organic fertilizer production lines, and agricultural waste.Founded in 1995, Richi Machinery is mainly engaged in the R&D and manufacturing of equipment required for pellet engineering such as feed mills, biomass wood pellet plant, organic fertilizer production lines, and agricultural waste.

Founded in 1995, Richi Machinery is mainly engaged in the R&D and manufacturing of equipment required for pellet engineering such as feed mills, biomass wood pellet plant, organic fertilizer production lines, and agricultural waste.Founded in 1995, Richi Machinery is mainly engaged in the R&D and manufacturing of equipment required for pellet engineering such as feed mills, biomass wood pellet plant, organic fertilizer production lines, and agricultural waste.

Get Quote

10 ton feed line in China

equipment required for pellet engineering such as feed mills, biomass wood pellet plant, organic fertilizer production lines, and agricultural waste.

Learn More

10 ton feed line in China

equipment required for pellet engineering such as feed mills, biomass wood pellet plant, organic fertilizer production lines, and agricultural waste.

Learn More

10 ton feed line in China

equipment required for pellet engineering such as feed mills, biomass wood pellet plant, organic fertilizer production lines, and agricultural waste.

Learn More

10 ton feed line in China

equipment required for pellet engineering such as feed mills, biomass wood pellet plant, organic fertilizer production lines, and agricultural waste.

Learn More

Start Animal Feed Pellet Production Line With RICHI Machinery Today

What kind of animal feed plant do you want to establish?

How many tons per hour about this plant you want to build?

Where is this animal feed plant going to be built?

When do you plan to start the operation?

Importance of Raw Material Pre-Treatment

Our feed production line is highly versatile, capable of producing a wide range of animal feeds to meet diverse nutritional needs. Here are the main types of feeds it can produce:

- Poultry Feed:

- For chickens, ducks, turkeys, and other birds.

- Includes starter, grower, and layer feeds, optimized for each stage of development.

- Poultry Feed:

- For chickens, ducks, turkeys, and other birds.

- Includes starter, grower, and layer feeds, optimized for each stage of development.

- Poultry Feed:

- For chickens, ducks, turkeys, and other birds.

- Includes starter, grower, and layer feeds, optimized for each stage of development.

- Poultry Feed:

- For chickens, ducks, turkeys, and other birds.

- Includes starter, grower, and layer feeds, optimized for each stage of development.

- Poultry Feed:

- For chickens, ducks, turkeys, and other birds.

- Includes starter, grower, and layer feeds, optimized for each stage of development.

- Poultry Feed:

- For chickens, ducks, turkeys, and other birds.

- Includes starter, grower, and layer feeds, optimized for each stage of development.

- Poultry Feed:

- For chickens, ducks, turkeys, and other birds.

- Includes starter, grower, and layer feeds, optimized for each stage of development.

This flexibility ensures our feed production line can support various industries, providing high-quality feed for animals at every stage of life.

In addition to a single shrimp feed granulator or shrimp feed extruder, we have a complete shrimp feed production line and can provide turnkey shrimp feed production engineering. We can provide the main equipment required for the entire shrimp feed production project, such as crushers, granulators, extruders, as well as some auxiliary equipment, such as conveying equipment, dust removal equipment, etc. As for the price of the entire shrimp feed production line, I need to first understand your specific needs, and then have our engineering designer customize a production plan for you. After the shrimp feed production plan is confirmed, we can calculate the price for you. To learn more about the prices of shrimp feed production equipment, please contact us immediately as we have a detailed price list.

In addition to a single shrimp feed granulator or shrimp feed extruder, we have a complete shrimp feed production line and can provide turnkey shrimp feed production engineering. We can provide the main equipment required for the entire shrimp feed production project, such as crushers, granulators, extruders, as well as some auxiliary equipment, such as conveying equipment, dust removal equipment, etc. As for the price of the entire shrimp feed production line, I need to first understand your specific needs, and then have our engineering designer customize a production plan for you. After the shrimp feed production plan is confirmed, we can calculate the price for you. To learn more about the prices of shrimp feed production equipment, please contact us immediately as we have a detailed price list.

In addition to a single shrimp feed granulator or shrimp feed extruder, we have a complete shrimp feed production line and can provide turnkey shrimp feed production engineering. We can provide the main equipment required for the entire shrimp feed production project, such as crushers, granulators, extruders, as well as some auxiliary equipment, such as conveying equipment, dust removal equipment, etc. As for the price of the entire shrimp feed production line, I need to first understand your specific needs, and then have our engineering designer customize a production plan for you. After the shrimp feed production plan is confirmed, we can calculate the price for you. To learn more about the prices of shrimp feed production equipment, please contact us immediately as we have a detailed price list.

In addition to a single shrimp feed granulator or shrimp feed extruder, we have a complete shrimp feed production line and can provide turnkey shrimp feed production engineering. We can provide the main equipment required for the entire shrimp feed production project, such as crushers, granulators, extruders, as well as some auxiliary equipment, such as conveying equipment, dust removal equipment, etc. As for the price of the entire shrimp feed production line, I need to first understand your specific needs, and then have our engineering designer customize a production plan for you. After the shrimp feed production plan is confirmed, we can calculate the price for you. To learn more about the prices of shrimp feed production equipment, please contact us immediately as we have a detailed price list.

In addition to a single shrimp feed granulator or shrimp feed extruder, we have a complete shrimp feed production line and can provide turnkey shrimp feed production engineering. We can provide the main equipment required for the entire shrimp feed production project, such as crushers, granulators, extruders, as well as some auxiliary equipment, such as conveying equipment, dust removal equipment, etc. As for the price of the entire shrimp feed production line, I need to first understand your specific needs, and then have our engineering designer customize a production plan for you. After the shrimp feed production plan is confirmed, we can calculate the price for you. To learn more about the prices of shrimp feed production equipment, please contact us immediately as we have a detailed price list.

In addition to a single shrimp feed granulator or shrimp feed extruder, we have a complete shrimp feed production line and can provide turnkey shrimp feed production engineering. We can provide the main equipment required for the entire shrimp feed production project, such as crushers, granulators, extruders, as well as some auxiliary equipment, such as conveying equipment, dust removal equipment, etc. As for the price of the entire shrimp feed production line, I need to first understand your specific needs, and then have our engineering designer customize a production plan for you. After the shrimp feed production plan is confirmed, we can calculate the price for you. To learn more about the prices of shrimp feed production equipment, please contact us immediately as we have a detailed price list.

In addition to a single shrimp feed granulator or shrimp feed extruder, we have a complete shrimp feed production line and can provide turnkey shrimp feed production engineering. We can provide the main equipment required for the entire shrimp feed production project, such as crushers, granulators, extruders, as well as some auxiliary equipment, such as conveying equipment, dust removal equipment, etc. As for the price of the entire shrimp feed production line, I need to first understand your specific needs, and then have our engineering designer customize a production plan for you. After the shrimp feed production plan is confirmed, we can calculate the price for you. To learn more about the prices of shrimp feed production equipment, please contact us immediately as we have a detailed price list.

In addition to a single shrimp feed granulator or shrimp feed extruder, we have a complete shrimp feed production line and can provide turnkey shrimp feed production engineering. We can provide the main equipment required for the entire shrimp feed production project, such as crushers, granulators, extruders, as well as some auxiliary equipment, such as conveying equipment, dust removal equipment, etc. As for the price of the entire shrimp feed production line, I need to first understand your specific needs, and then have our engineering designer customize a production plan for you. After the shrimp feed production plan is confirmed, we can calculate the price for you. To learn more about the prices of shrimp feed production equipment, please contact us immediately as we have a detailed price list.

In addition to a single shrimp feed granulator or shrimp feed extruder, we have a complete shrimp feed production line and can provide turnkey shrimp feed production engineering. We can provide the main equipment required for the entire shrimp feed production project, such as crushers, granulators, extruders, as well as some auxiliary equipment, such as conveying equipment, dust removal equipment, etc. As for the price of the entire shrimp feed production line, I need to first understand your specific needs, and then have our engineering designer customize a production plan for you. After the shrimp feed production plan is confirmed, we can calculate the price for you. To learn more about the prices of shrimp feed production equipment, please contact us immediately as we have a detailed price list.

If you need further information, please contact us