Find out all the feed mill machinery for setting up an animal feed mill plant, from raw material processing to pellet feed finished

01

Raw Materials Processing

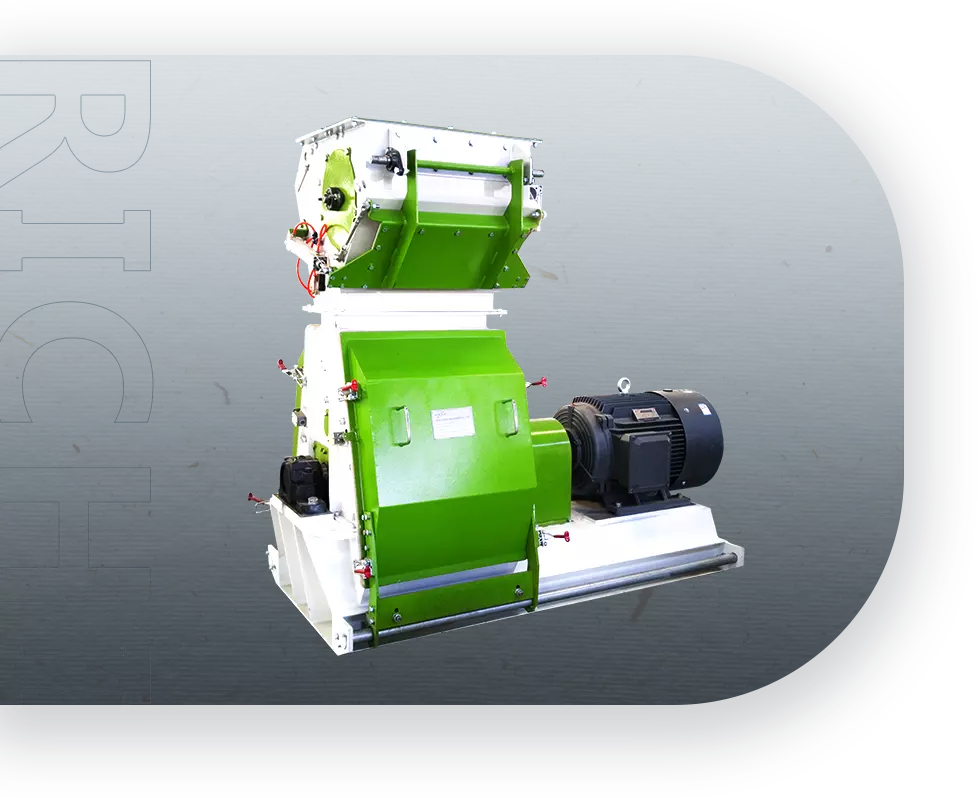

Hammer Mill for Raw Materials

Precise output, perfect grinding for the most demanding applications. Flexible configurations, easily replaceable wear plates, precision balancing to protect and extend service life. Flexible and versatile crushing, pelletizing and processing equipment for the wood pellet, biomass fuel, animal feed mill and pet food industries.

02

Mixing of Formulas

Mixing Machine

Important equipment for modern agriculture and animal husbandry. Its functions include achieving uniformity of feed ingredients, preventing selective feeding and improving nutrient utilization. The advantages of mixers are their precision, cost-effectiveness, flexibility, reduced labor and improved animal health. Ultimately supporting sustainable and efficient feed production and agricultural practices.

03

Efficient Pelletizing

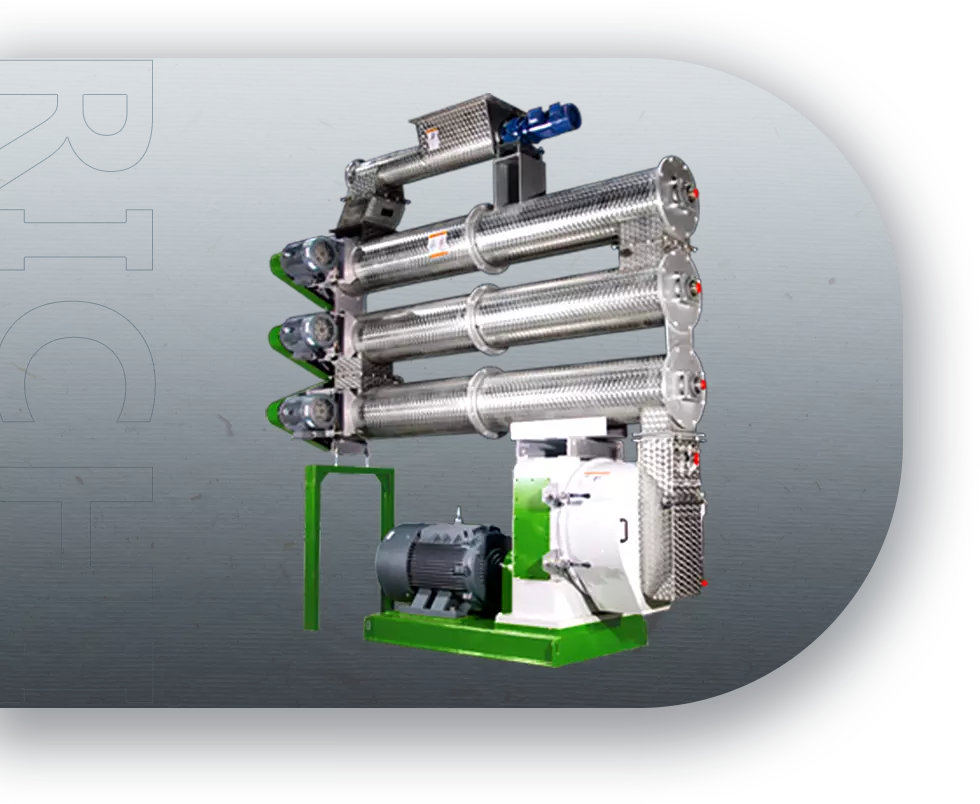

Pellet Machine for Animal Feed

RICHI Machinery has been dedicated to the development and production of feed mill equipment. The SZLH series pellet mills is ideal for agricultural, aquatic and pet food pelletizing applications. Whether designed for commercial investment projects or feed pellet production programs for professional farms, RICHI pellet machines operate at optimum capacity and produce high quality pellets using sustainable, innovative and environmentally friendly technologies.

04

Processing After Pelletizing

Pellet Cooling Machine

By effectively reducing the temperature of newly formed particles, it plays a key role in particle production. This cooling process can improve the durability, moisture stability and overall quality of particles, while preventing agglomping and improving storage and processing characteristics. Particle coolers are an important part of ensuring that the final product meets the required standards and maintains its integrity throughout the life cycle.

05

Finished Pellets Processing

Screening for Feed Pellet

By promoting pellet size separation, quality control and pellet distillation, it plays a vital role in the animal feed pellet production. It can improve product quality, process efficiency and safety, while ensuring compliance with industry regulations. Whether it is to remove pollutants, classify materials, or achieve specific pellet size distribution, screening equipment is a multi-functional tool.

06

Packing & Storage

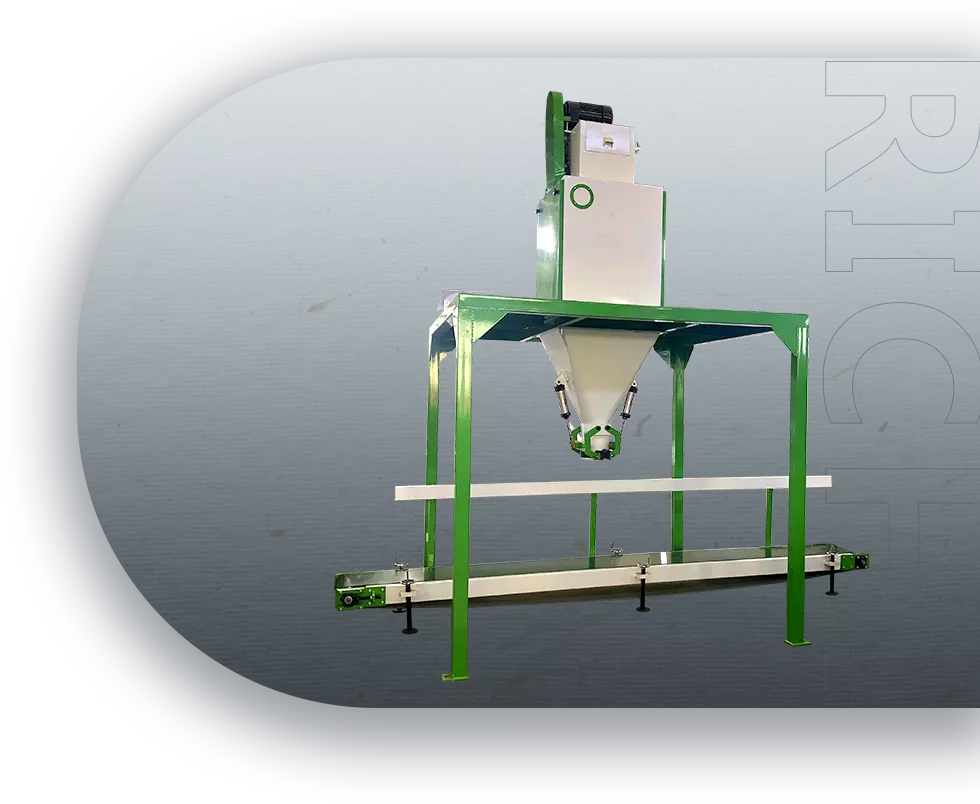

Pellet Packaging System

While ensuring accurate weighing and labeling, the pellet packaging system also plays the role of packing, protecting and preserving pellets. It plays a key role in maintaining product quality, promoting efficient distribution and meeting regulatory standards. Whether it is a pellet production system used in animal feed mill plant or applications in other industries, an efficient and reliable packaging system is the key to successfully delivering pellets to consumers.

07

Auxiliary Equipment

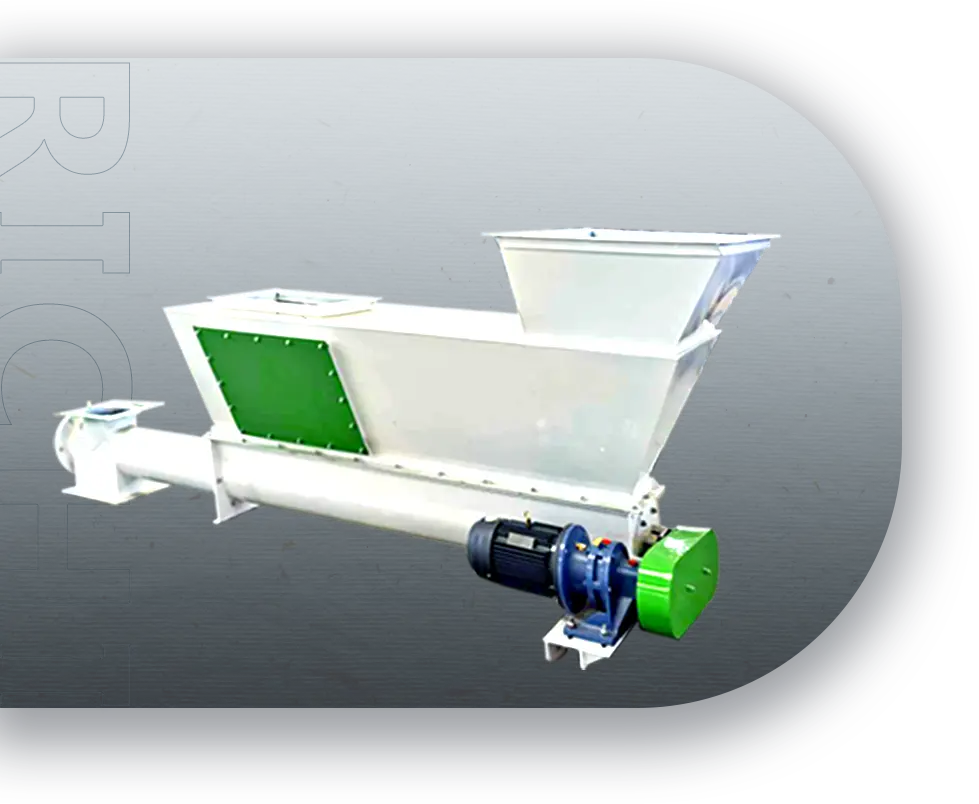

Conveyor System

Promote the efficient movement of raw materials, intermediate products and finished particles throughout the production process. Their practical application and role are essential for simplifying operations, maintaining product quality and ensuring the overall efficiency of feed pellet production.

08

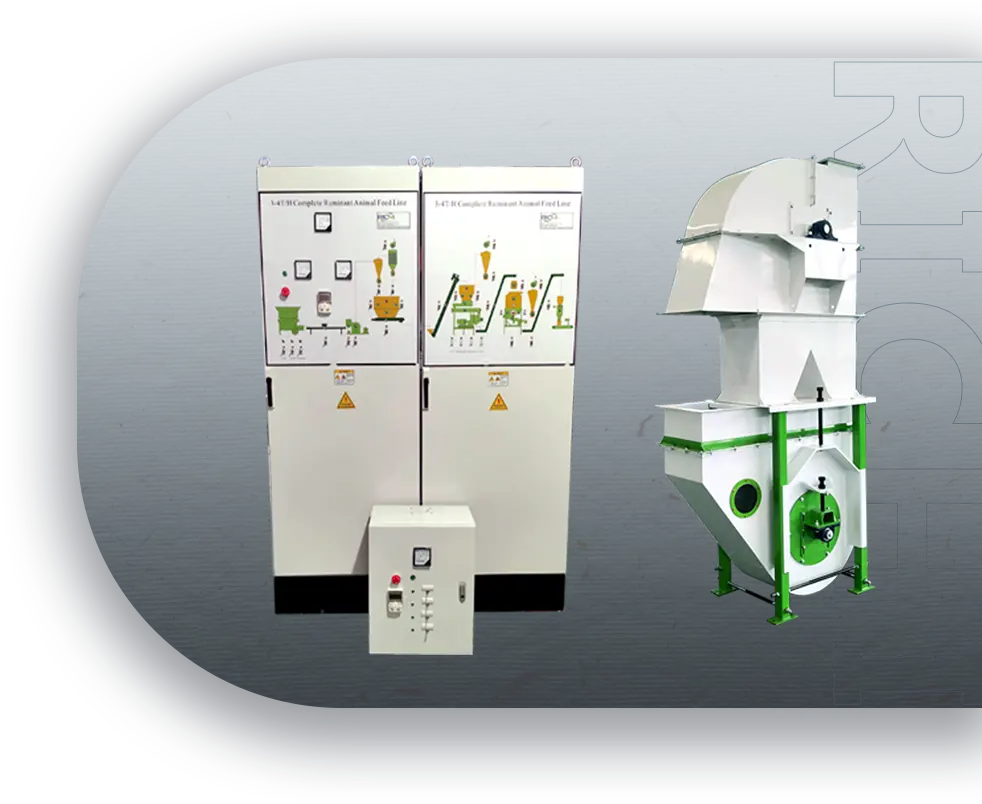

Electronic Control System

Electronic Control System

The electronic control system of RICHI Machinery's animal feed pellet production line has the advantages of accuracy, automation, remote monitoring, customization, energy saving, safety and scalability. These advantages help to improve production efficiency, product quality and operation convenience in the feed manufacturing process.

09

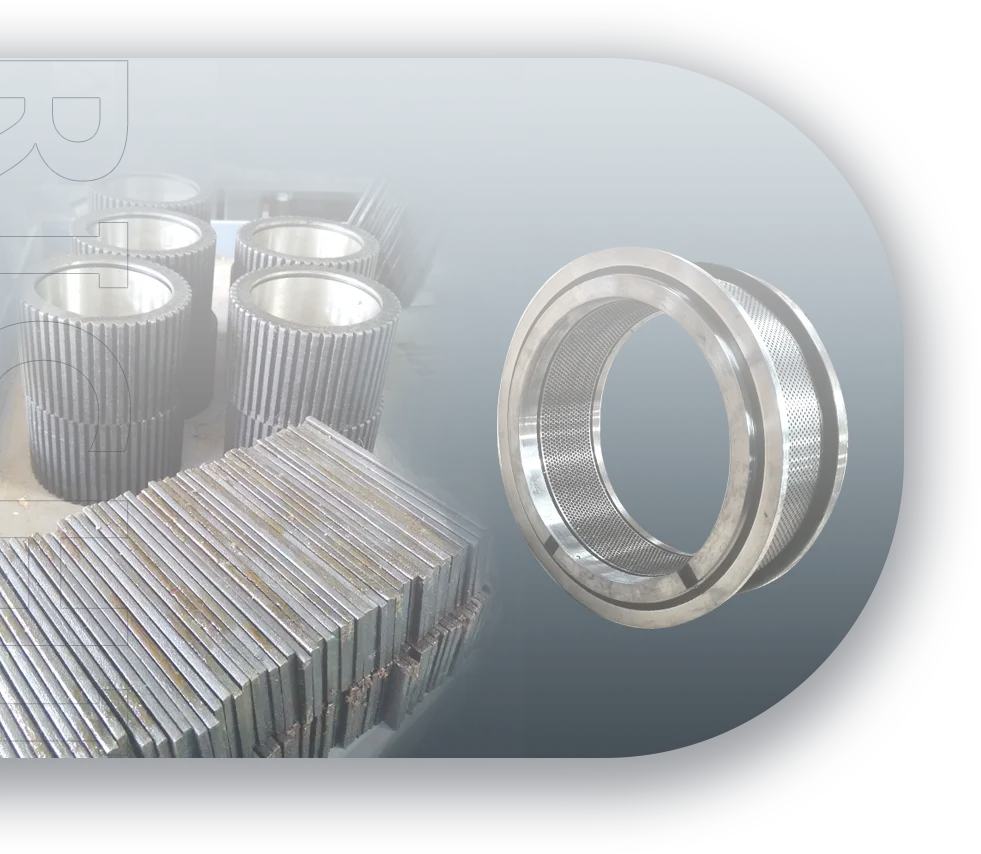

Accessories & Spare Parts

Accessories for Feed Mill Plant

RICHI Machinery can provide you with almost all the accessories that animal feed mill equipment may need. For example: hammer, ring die, pressure roller, screen, etc. When you are looking for replacement parts, RICHI Machinery is the best choice. Even if you have a hammer mill or pellet machine from another manufacturer, please contact us to discuss whether there is an alternative.

CUSTOMER CASES

Contact us immediately to discuss the plan of the feed mill plant and customize the complete animal feed production line.

Service Process

RICHI Machinery always brings customers a complete, high-level, scientific and simple service process, and is committed to maintaining a good experience for customers.

01

Online communication: Engage in seamless virtual discussions to address queries and provide information.frame

02

Program confirmation: Validate and finalize project details and specifications for a clear production roadmap.

03

Start of production: Initiate the manufacturing process, transforming concepts into tangible products.

04

Equipment testing: Rigorously assess equipment functionality and performance to ensure reliability.

05

Delivery: Safely transport and deliver products to every ports in this world.

06

Installation: Professionally set up and integrate equipment for efficient operation.

07

After-sales service: Offer ongoing support, maintenance, and assistance to enhance equipment longevity.

08

Lifelong service: Provide continuous support and solutions throughout the equipment's operational lifespan.